Our Systems

are designed with a precise vision: optimizing production processes, improving performance and economic results for our clients. Flexible and functional technology is the result of constant updating of our knowledge and the continuous search for perfection.

Technical choices about development are constantly being evaluated based on the context and objectives of the project plus specific customer needs.

RD Automation srl develops standard and customer specific software to answer all customers questions and needs. Our system enables you to be able to analyze all the data of your lines and plants, all over the world.

At any time, using your smartphone for example, you will have the possibility to be updated about what is happening within your company. We can collect data from the machine and send it to you or an IT department, but we can also do the same in reverse: Send production orders from the office to the machine to make sure the production will never produce "wrong" orders anymore!

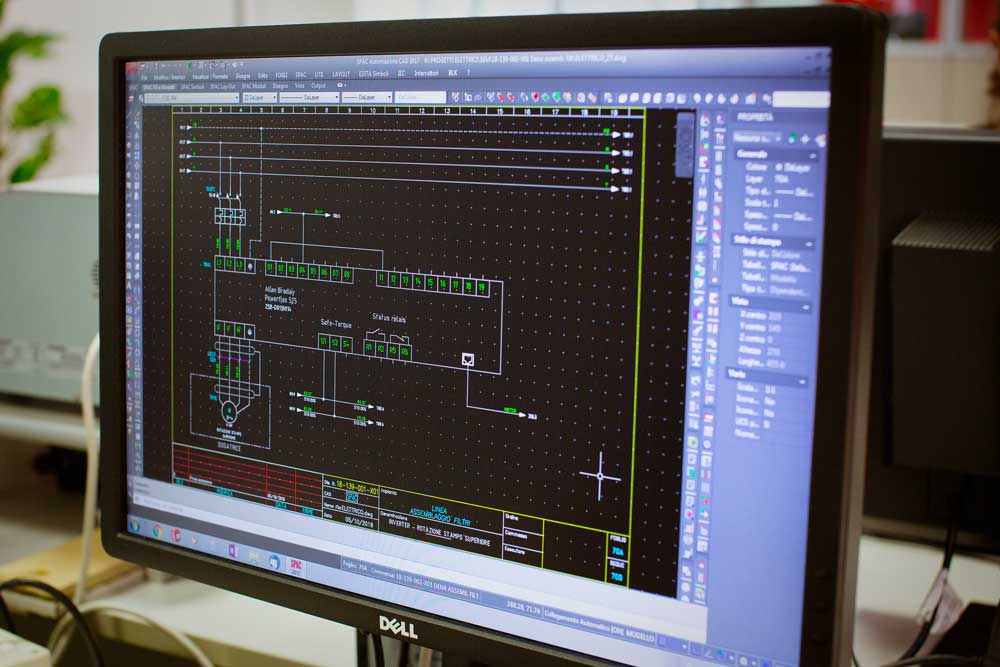

Study and planning of the hardware side of any project, fully automated lines and robotized islands

− Project analysis, consulting on the components and systems to be installed in collaboration with the customer

− Design of electrical and pneumatic diagrams

− Technical consultancy from "A" to "Z" during the execution of the projects. Together, we can overcome all mechanical, electrical and software challenges we face during the development of your machine.

− Modular and integral testing of all functions at clients location (constructor)

− Machine safety consulting

− Drafting of technical files

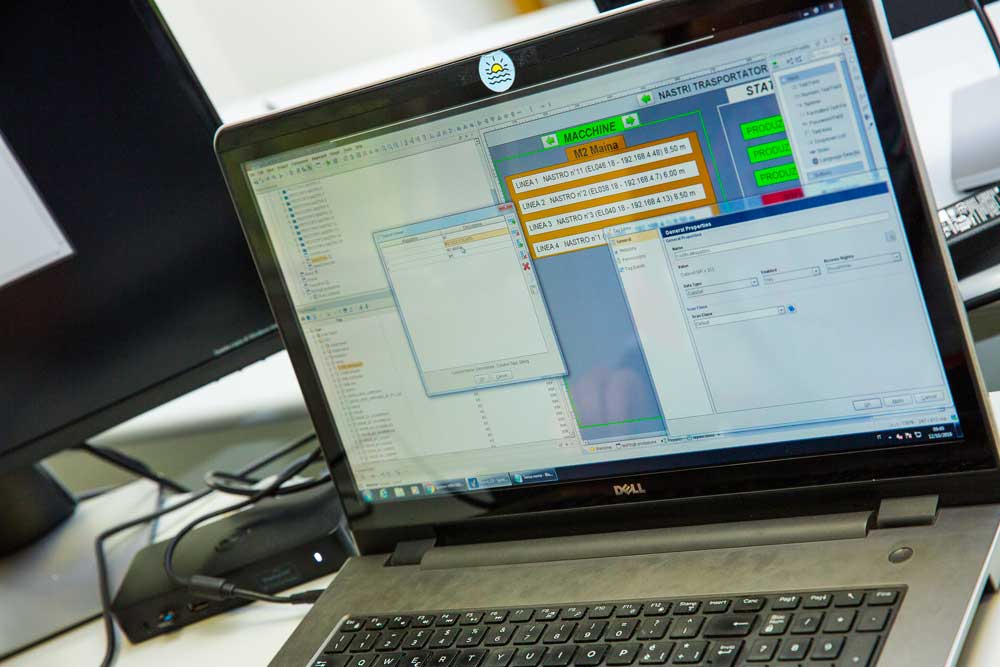

Software development SCADA, MES, Supervision, production monitoring in real time

Would you like to monitor the production from everywhere in your plant, continuously?

Would you like a detailed overview of your production costs?

Would you like to know the efficiency and profit of your machine park, analyzing where you have chances to optimize production cycles?

Software development PLC* e HMI**

− Study and planning of PLC and HMI software in cooperation with our clients

− Development of PLC and HMI software

− Modular and integral testing of all functions at clients location (constructor)

− Final commissioning in production environment at end user, including production assistance

− IInstruction and training of operators and maintenance personnel

− Remote assistance support for troubleshooting and problem solving from anywhere in the world.

System integretor Rockwell Automation

System used Siemens | Weintek | Proface

* programmable logic controller | ** Human-Machine Interface